Bubble Canopy Do 435- fictional

Based on current knowledge, the Do 435 is believed to have been a variant of the 335 featuring a side-by-side cockpit (Monogram Close-Up 21).

"A post-war allied intelligence report stated that the Do 435 was a modified version of the Do 335 with a wider cockpit previously mentioned, cabin pressurization, radar equipment and long-span wooden outer wing panels. The project was to be powered by two 2500 hp Jumo 222 engines."

Manfred Griehl in his book 'Dornier Do335, 435, 635' comes to a similar conclusion. He does quote an original overview from the Dornier factory:

"Die Do 435 stellt die folgerichtige Weiterentwicklung der Do 335 als Zweisitzer dar."

"The Do 435 represents the logical advancement of the Do 335 as a two-seater."

The reader will notice that most sources are secondary sources. More about that later.

In some sources (Source: Miranda), the 435-222 is also referred to as the P.238. That does in fact seem unlikely since the P.238.1 is fairly well documented (Source: Dornier Do 335, 435, 635 Manfred Griehl), see image below.

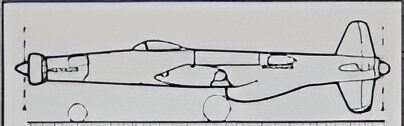

Cross section and general layout of the Do 435 two-seater.

There is also an unverified version rumored to have been equipped with two Jumo 222 engines and a bubble canopy, which occasionally surfaces online and in some print media. Despite the absence of any documented evidence, the concept remains captivating enough to consider developing a model kit, even though it currently resides in the realm of speculative designs. For the sake of clarity, the version shall be referred to as the 435-222.

The fuselage of the 435-222 was seemingly extended, thereby increasing the overall weight of the aircraft. A larger wing would hence be plausible and here the P.237/3 might serve as a basis (Source: Dornier Do 335, 435, 635 Manfred Griehl).

Several drawings of the 435-222 can be found online, see below.

According to the Dornier Museum (E-Mail 19.09.2023) most Dornier documents were burned towards the end of the war. So, if there ever was any documentation to support a bubble canopy, Jumo 222 powered 435, it is now forever lost. It is however not completely unlikely that these design features were at some point considered by Dornier engineers in their quest to boost aircraft performance.

The fact that no information on the aircraft is available, implies that the design has to be reverse engineered. This is accomplished by combining know subsystems with characteristics design features of the 335. After all, the design would most likely be based largely on the 335. For the subsystems, information, auch as drawings and images, are available.

General characteristics

Crew: 1

Length: 17.3 m

Wingspan: 18.3 m

Height: 4.7 m

Powerplant: 2 × Jumo 222 E / F:, with two-stage two-speed centrifugal supercharger and trio of aftercoolers. The Jumo 222 E/F’s maximum power at 3,000 rpm was 2,500 hp (1,864 kW) for takeoff and 1,930 hp (1,439 kW) at 29,528 ft (9,000 m). Climbing power at 2,700 rpm was 2,220 hp (1,655 kW) at sea level and 1,680 hp (1,253 kW) at 36,000 ft. Cruising power at 2,500 rpm was 1,840 hp (1,372 kW) at sea level and 1,400 hp (1,044 kW) at 34,689 ft (11,000 m).

(Source: https://oldmachinepress.com/2021/06/05/junkers-jumo-222-aircraft-engine/)

Guns: 2x MG 151 20mm and 2x MK 103 30mm (wing mounted)

So here are a few drawings and renderings from that design process. The model is available HERE.