Focke Wulf with BMW 802 engines- model kit development

Initially, it was hypothesized that this design was fundamentally based on the FW 190 fuselage, essentially a standard FW 190 modified to integrate the large BMW 802 engine. This hypothesis is further substantiated by several references in the literature, such as those provided by H. Norwarra.

If this assumption were correct, the depicted shape of the fuselage must be somewhat inaccurate. The fuselage appears disproportionately short, and the configuration of the vertical tail plane (VTP) deviates significantly from that of the Focke-Wulf 190. The design, as initially proposed by Dipl.-Ing. Ludwig Mittelhuber, lacks a verifiable source according to luft46.com. Mittelhuber was reportedly involved in various Focke-Wulf projects, including the TW 200 and Ta 154.

Integration study FW 190

The images below depict a prospective integration of the BMW 8011 engine into an FW 190 fuselage. It is evident that the outer circumference of the BMW 8011 engine is significantly larger compared to the standard BMW 801. Additionally, the engine has an increased length. These differences would necessitate extensive modifications to the fuselage, both to the overall structure and to accommodate the resultant shift in the center of gravity.

Source Material (primary)

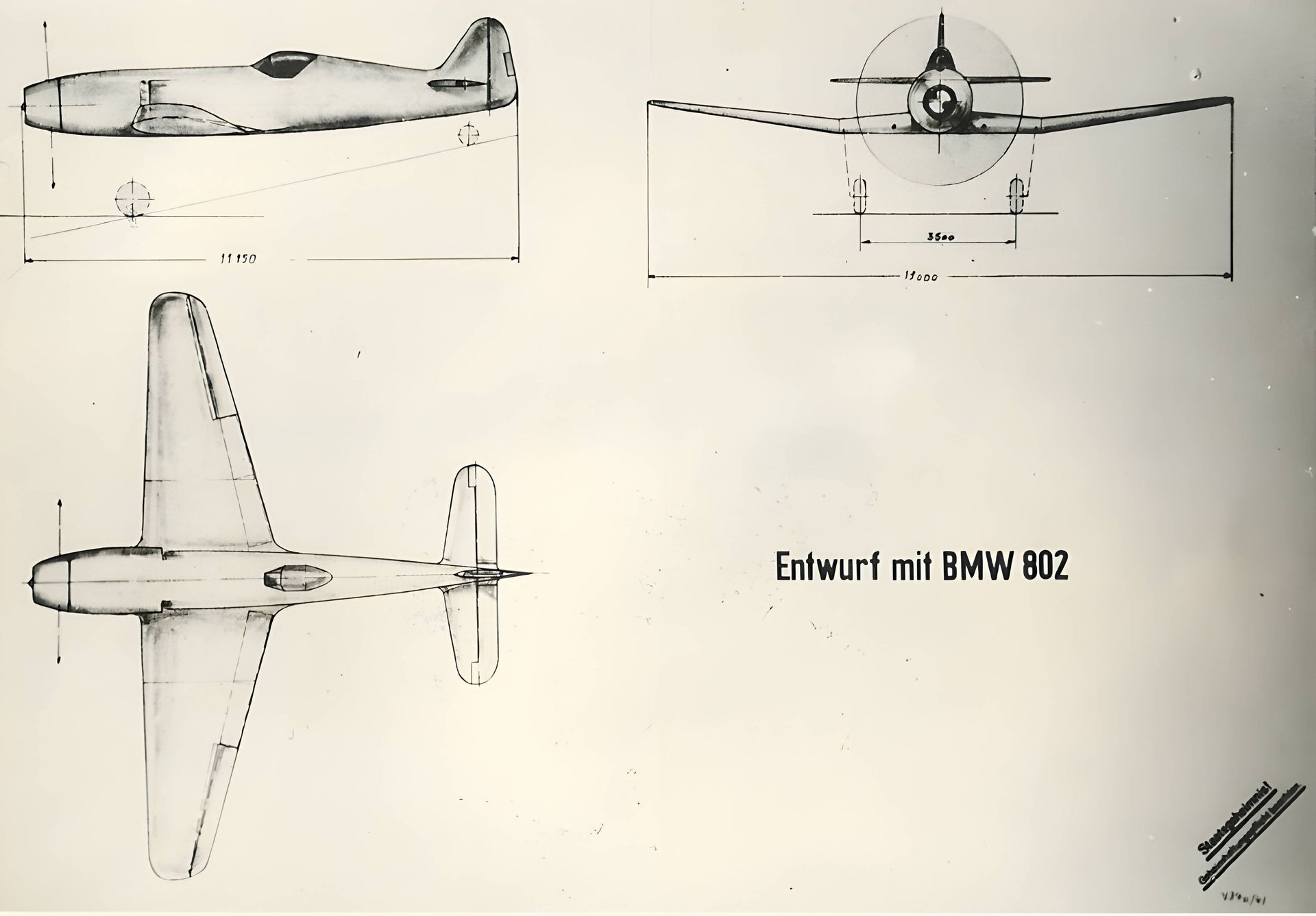

Further sources are required for comprehensive analysis. Subsequent investigation yielded a drawing of a Focke Wulf aircraft equipped with a BMW 802 engine. The dimensions of the drawing are 14 cm by 10 cm. Evidence on the reverse side suggests it was likely discovered by Heinz Norwarra.

H. Norwarra states the following in his book (Die Deutsche Luftrüstung 1933-1945), we're the same image is shown:

Weiterentwicklung FW 190 D mit 18-Zylinder BMW 802 Startleistung 2450 PS. Propellerhaube vorn offen für Kühlluftzuführung. Bewaffnung 4 MK, zwei über Motor, zwei in Flügelwurzel. Spannweite 13,00 m, Länge 11,15 m.

Engl.

Further development FW 190 D with 18-cylinder BMW 802 starting power 2450 hp. Propeller hood open at the front for cooling air supply. Armament 4 MK, two over engine, two in wing root. Span 13.00 m, length 11.15 m.

Strangely enough, it is described by Norwarra as a development of the FW 190 D. Nothing seems to support that statement at this point.

According to Gunston (2006), the development of the BMW 802 engine was discontinued in 1942, coinciding with the completion of the first D-0 model. The armament depicted in the drawing includes two MK 108 cannons positioned above the engine, a configuration that appears impractical given the limited available space. Contrary to this, luft46.com asserts that the aircraft was unarmed. Based on my assessment, a more plausible armament configuration would include two MG 131 machine guns, supplemented by MK 108 cannons mounted in the wings.

Reference:

Gunston, B. (2006). World Encyclopedia of Aero Engines: From the Pioneers to the Present Day (5th ed.). Stroud, UK: Sutton. ISBN 0-7509-4479-X.

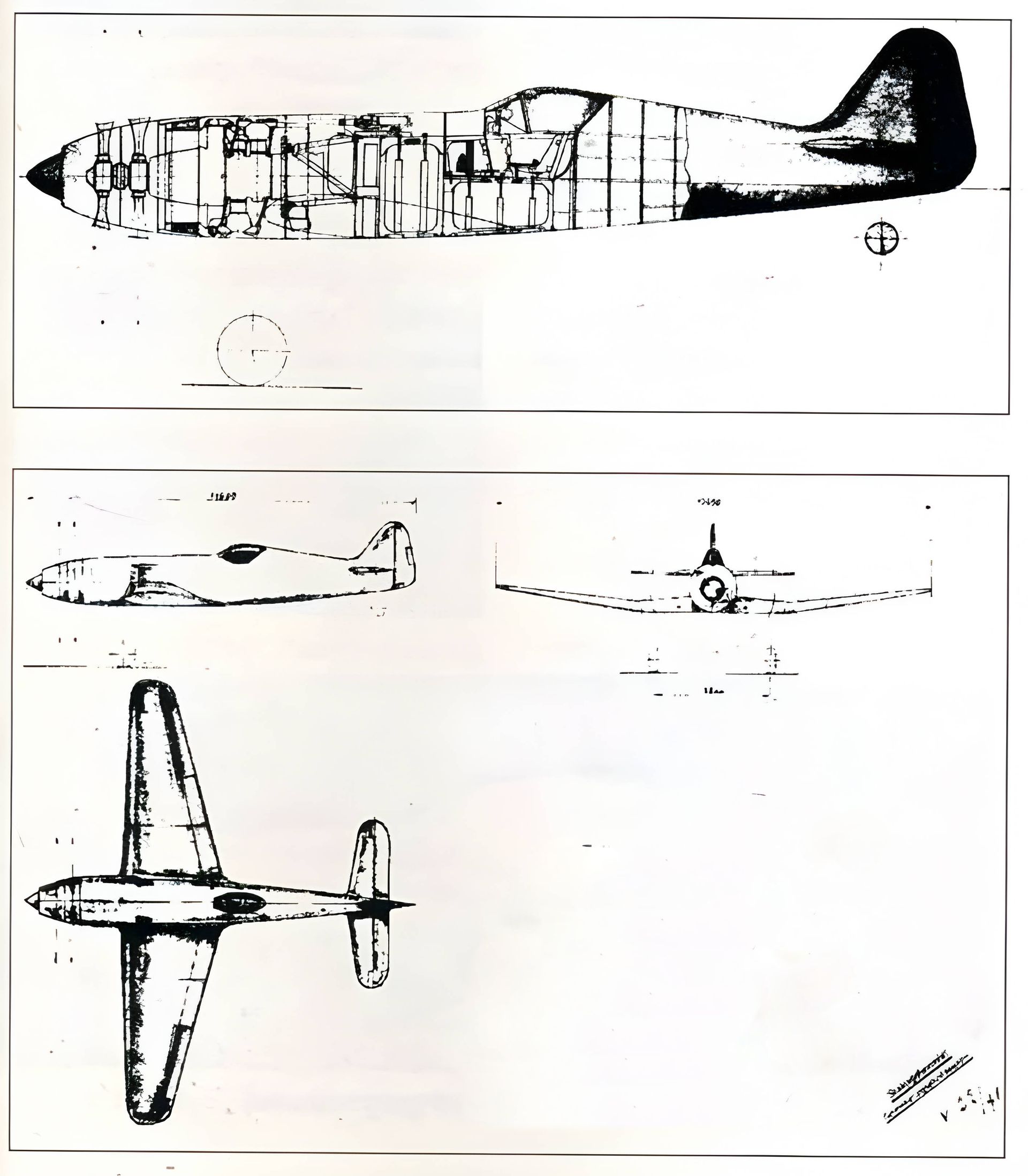

Furthermore, in 'Flugzeug Classic 2/2005' a gentleman called Horst Lob (Bremen) published the following image, in the section ' letter to the editor'. This is the only source of a counter rotating prop configuration.

Apart from the image, the gentleman could not provide further information apart from some speculation. The image was titled 'Entwurf with BMW 8011' But, this is indeed the first 3- view drawing of that FW with the infamous BMW 8011.

As for the BMW 8011, the following statement were found on the https://www.secretprojects.co.uk/ forum:

From BMW Aero Engines by Jakobs, Kroschel, and Piere... "33 projects codenamed P 8000 to P 8032 are documented for the period up to April 1942 alone. All of them were either based on the BMW 801 (13 projects) or on the 802 (20 projects). For the most part, the main focus of the documented projects was on internal and external engine aerodynamics, looking for example at charge-air and cooling air feed, or at a double spinner with or without an inlet cone."

This seems to support the assumption that the BWM P.8011 was a sub-version of the 802 (or 801?). Information about that engine was at some point forwarded to BMW which integrated it into their design. As an example, P.8008 is depicted below. Wikipedia suggests two turbochargers for the P.8011. I do not have access to any source supporting that statement. P.8011 might as well featured 3 turbo chargers as P.8008.

The wing of the Mittelhuber fighter also differs significantly from the FW 190 wing, see below (compared here to FW 190 D-9 wing). The sweep angle of the leading edge is smaller, the wing tip pointier. Wing span is 13.00 m compared to 10.51 m for the D-9.

Overall. I have to assume, that Mittelhuber's design is not closely based on the 190 after all. Also, FW/ Mittelhuber would sporadically update the design with input from BMW, that was working on numerous sub- versions for the BMW 802. So at this point it can also be concluded that this aircraft was not a sub- variant of the FW 190.

The model kit (1/48 and 1/72) is available here: LINK